GKN – Tag Milling Automation

The Problem

The brief was to supply a solution to enable them to machine a tag slot in ten sizes of CV joints with a version for a cotter pin. The requirement of the brief was to deliver the part conveyor to conveyor in a 15 second cycle.

The concept was to load the incoming parts from the main transfer conveyor we installed a section into the machine its self that allowed GKN to have an uninterrupted flow of parts through the assembly line.

The Solution

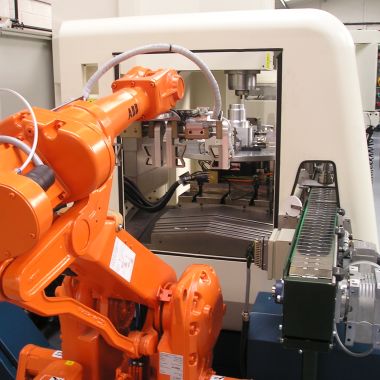

A Hardinge VMC 600 milling machine centre undertook the main machining operation. As the main supplier we contracted ABB robotics to supply the 6-axis robot to facilitate the loading and unloading of the part from a bespoke 4 positioned indexing table.

Agemaspark commissioned Halifax numerical control (HNC) a highly respected machine tool retrofitting company to integrate the PLC and software interface to machine and robot. All the design and project management responsibilities were undertaken by Agemaspark the 2 complete cells where built at our facility in Doncaster and fully trailed and tested with full run of approval trials before shipment to GKN at Birmingham. Complete operator training was also undertaken for the each of the eighteen man cell team. The first cell being installed in March 2005 and the second cell in October 2005.

The Results

These were the results